Smart Factory Approach

Smart Factory

Use high degree of Automation and Informatization runs through the whole process to control production, drives quality improvement and plant operation efficiency.

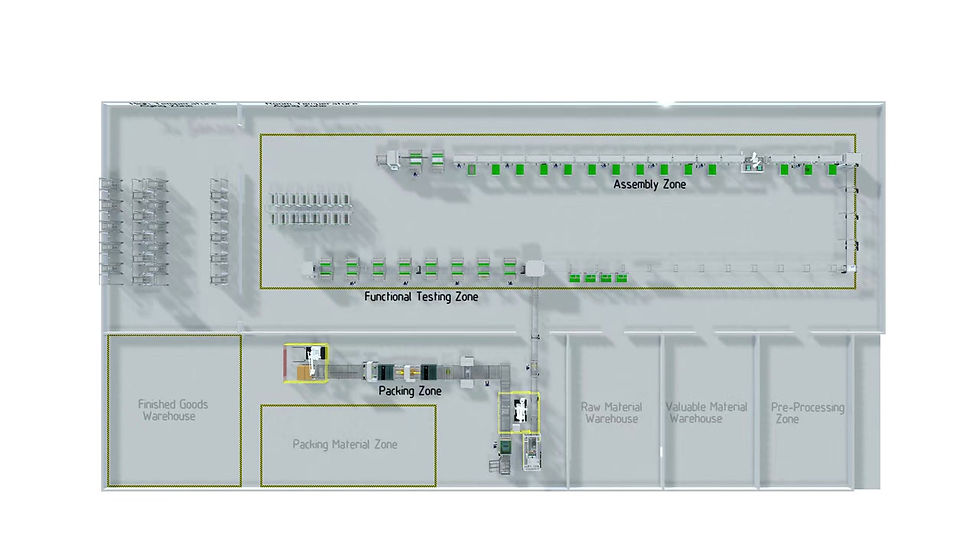

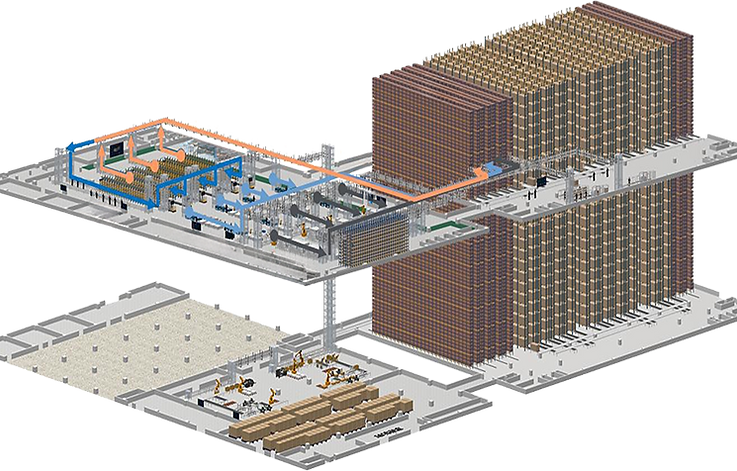

AI Server End-to-End Factory

-

From material management, PCBA& case assembly, testing and packaging, to finished product shipping

-

High degree Automation

-

Informatization runs through whole process

-

Digitalization drives quality improvement and plant operation efficiency

-

Automatic distribution of materials

-

Mixed production of joint single and bulk single products

-

Daily Output up to 800pcs

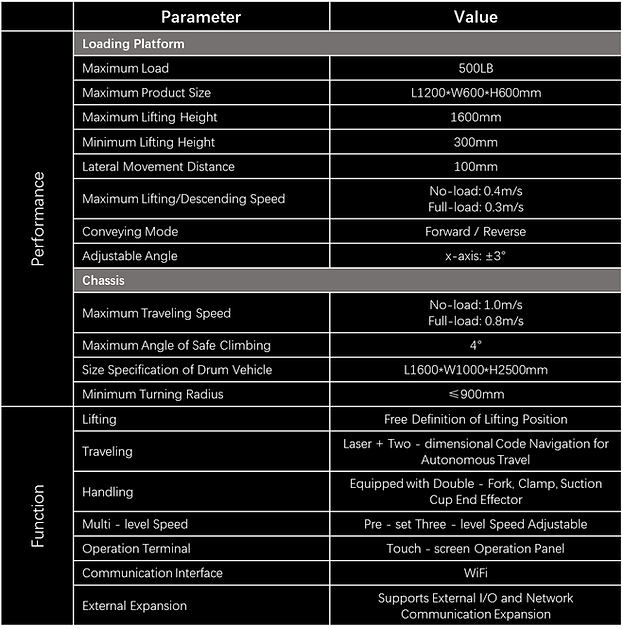

Auto Lift & Installation

Intelligent, driverless transport systems that automate material handling in modern facilities.

ShopFloor System

Real-time, computerized system that bridges enterprise planning (ERP) and factory floor control, providing end-to-end visibility and control of production operations.

Production Tracking & Traceability

-

Real-time monitoring of WIP (Work in Progress)

-

Full genealogy tracking (materials, components, operators)

-

Electronic batch records compliance

Process Management

-

Standardized work instructions

-

Digital SOP enforcement

-

Version-controlled recipe management

Quality Integration

-

SPC (Statistical Process Control) integration

-

Non-conformance tracking

-

First-pass yield analysis

Performance Analysis

-

OEE (Overall Equipment Effectiveness) calculation

-

Downtime root cause analysis

-

KPI dashboard visualization

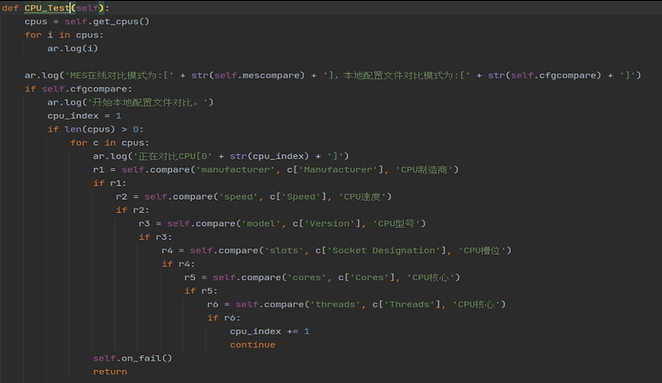

Testing Software

An advanced quality validation platform designed to verify functionality, performance, and reliability of hardware/software products through automated and manual testing methodologies.

-

40-70% faster test cycle completion•

-

60% reduction in escaped defects•

-

30% lower testing labor costs

Ready to get new factory?

contact us now